Boemo ba Khoebo

Retek e fana ka lethathamo le felletseng la litharollo tse tsoetseng pele tsa theknoloji lefatšeng ka bophara.Baenjineri ba rona ba laetsoe ho tsepamisa boiteko ba bona ho nts'etsopele ea mefuta e fapaneng ea lienjineri tsa motlakase tse sebetsang hantle le likarolo tse tsamaeang, ho feta moo re fana ka lits'ebeletso tsa tlhahiso ea boleng bo holimo le tsa CNC le lits'ebeletso tsa tlhahiso ea likhoele lefatšeng ka bophara.

Lihlahisoa tsa Retek li fanoa ka bongata bakeng sa libapali tsa bolulo, litsi tsa moea tsa indasteri, lihlahisoa tsa boithabiso, lisebelisoa tsa elektroniki, likepe tse lebelo, lifofane, lits'ebeletso tsa bongaka, lisebelisoa tsa laboratori, mechini ea makoloi, koloi le lisebelisoa tsa lapeng.

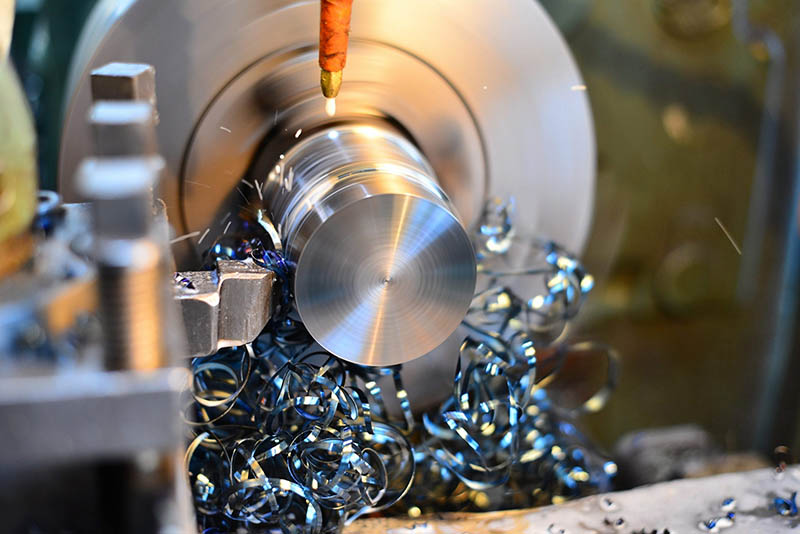

Joalo ka karolo ea bohlokoa ea khoebo ea Retek, Teknic e na le lilemo tse fetang 5 tsa boiphihlelo ba mochini oa CNC le boiphihlelo bo fetang lilemo tse 10 ba ho etsa lintho.Re sebetsa ka ho khetheha litšebeletsong tsa machining tsa CNC ho tloha ho moralo, prototyping e potlakileng, le likarolo tse rarahaneng tsa geometry ho isa tlhahiso ea molumo o tlase kapa o moholo.E ikemiselitse ho hlahisa likarolo tse entsoeng ka mochini oa boleng bo holimo ho latela tekanyetso ea hau le tlhoko ea nako ea pele, Teknic e ka nka mehopolo kapa meralo ea hau ho hlahisa tlhahiso ea 'nete ka matsatsi a seng makae ka boits'oaro, boleng le boqapi ba rona.

Retek e netefalitse ka botlalo boleng ba lihlahisoa tsa CNC le khotsofalo ea bareki ho latela ka tieo lipehelo tsa litekanyetso tsa ISO melaong ea melao ea tsamaiso.Re sebelisana 'moho le mekhatlo ho pota lefatše ho etsa likarolo tse entsoeng ka mokhoa o nepahetseng ka thepa e fapaneng e netefalitsoeng, ho kenyeletsoa lipolasetiki le litšepe tse fapaneng.Lihlahisoa tseo re li entseng li 'nile tsa sebelisoa haholo sebakeng sa lifofane, tsa bongaka, tsa likoloi, tsa puisano, tsa mechine, tsa elektroniki, tsa lisebelisoa tse bohlale, lipapali le liindasteri tse ling.

Retek e tsepamisitse maikutlo ho tshilo ea CNC, ho fetoha ha CNC, machining a Switzerland, khatiso ea 3D, le prototyping e potlakileng.Hape re ka fana ka lits'ebeletso tsa ho etsa li-die casting, ho etsa ente, le lits'ebeletso tsa masela a tšepe.Ntle le khetho e pharaletseng bakeng sa machining, re boetse re fana ka letoto la likhetho tsa morao-rao ho ntlafatsa litlolo kapa ho ntlafatsa thepa ea mochini.Likarolo tsa rona tse entsoeng ka mochini hangata li sebelisoa ke lik'hamphani tsa boenjiniere ba litsebi le baetsi ba lisebelisoa tsa mantlha lefatšeng ka bophara.Re sebeletsa palo e kholo ea liindasteri tse kenyelletsang Likoloi, Electronics, Optics, Medical, Oli & Gas, Tool & Die, meno, lisebelisoa tsa ho shebella, lithuthuthu le libaesekele, joalo-joalo.

Re na le tharollo e potlakileng, e sebetsang, le e sebetsang bakeng sa projeke ea hau ea mochini oa CNC.Sena se u fa monyetla oa ho etsa liteko tsa prototyping tsa sebopeho, ho lekana, le tšebetso, kapa bakeng sa tlhahiso ea likarolo.Tekolo le tlhahlobo ea ts'ebetso ea sehlahisoa li nolofalletsa sehlahisoa sa hau ho ntlafatsoa pele se se isa 'marakeng.

Rea u amohela ho re romella RFQ bakeng sa qotsa, ho lumeloa hore u tla fumana lihlahisoa le litšebeletso tse baballang ka ho fetisisa mona Teknic!

Pono ea Khampani

Ho ba mofani oa tharollo ea motsamao ea tšepahalang.

Thomo

Etsa hore bareki ba atlehe 'me basebelisi ba ho qetela ba thabe.

Ke Hobane'ng ha U Re Khetha?

●Mekhatlo ea phepelo e tšoanang le ea lik'hamphani tse ling tsa sechaba.

●Liketane tse tšoanang tsa phepelo empa li-overheads tse tlase li fana ka melemo e sebetsang hantle.

●Sehlopha sa boenjiniere sa lilemo tse fetang 15 se hiriloe ke lik'hamphani tsa sechaba.

●Phetoho e potlakileng nakong ea lihora tse 24 ka sebopeho sa taolo e pharalletseng.

●Keketseho e fetang 30% selemo se seng le se seng lilemong tse 5 tse fetileng.