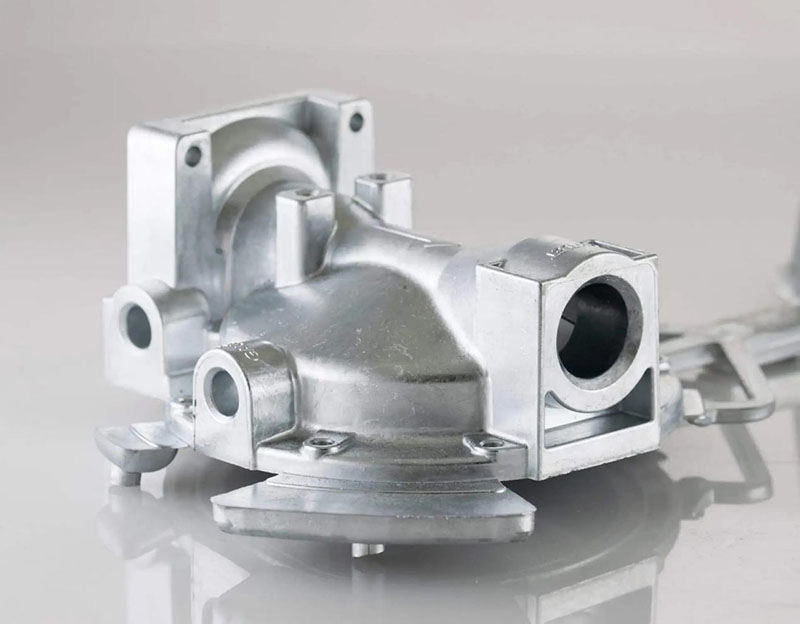

Teknic ke moetapele oa lefats'e oa "die casting", ka bareki ho tloha ho lik'hamphani tse kholo tse etsang lisebelisoa ho isa indastering ea likoloi ho tloha mohopolong oa moralo, ho isa tlhahiso le ho paka.

Re fana ka zinc die casting ho tloha ho moralo le tlhahlobo ea hlobo, ho isa ho tlhahiso ea likarolo tsa zinki, ho phethela le ho paka ho tsoa ho litlhaloso tse rarahaneng tsa moralo ebe re li fetola sehlahisoa se felileng.

Teknic e etelletse pele lik'hamphani tsa zinc die casting ka lilemo tse 10.Ho tloha ha e thehoa, re fetohile moetapele oa maemo a lefats'e ea sebelisang theknoloji le litsebi tse nang le boiphihlelo ho etsa li-die castings tsa boleng bo holimo.Re tsepamisitse maikutlo ho boleng le ho rarolla mathata Chaena.motheo oa setsi sa tlhahiso ea Zinc Molding.

Libopeho tse rarahaneng le ho mamellana ka thata

Zinc die casting e hlahisa li-cavity tse ngata, libopeho tse rarahaneng le ka har'a mamello e haufi ho feta mekhoa e meng e mengata ea tlhahiso.Ntle le ho hlahisa molumo o phahameng oa likarolo tse batlang li tšoana, e hlahisa mocheso o matla le ho roala likarolo tse hanyetsanang tse tsitsitseng, ha li ntse li boloka mamello e haufi haholo.

Mokhoa oa "die casting" o fa baqapi monyetla oa ho boloka litšenyehelo ka ho kopanya likarolo hore e be mofuta o le mong oa letlooa.Ka hona, ho ka felisa ts'ebetso ea bobeli joalo ka machining.Zinc die castings li entsoe ka katleho e le li-bearings (ho felisa li-alloys tsa bronze), li-rivets, 'me li ka kenya likhoele.Ka lebaka la melemo ena, li-die castings li fumaneha liindastering tse fapaneng tse kenyelletsang likoloi, lisebelisoa tsa meaho, lisebelisoa tsa elektroniki, thepa ea lipapali, jj.

Hoa lokela ho hlokomeloa hore mamello e tloaelehileng ea indasteri e ka finyelloa le / kapa ea fetisoa, haeba ho hlokahala bakeng sa moralo oa karolo.Leha ho le joalo, ho na le lintlha tse ngata tse lokelang ho nkoa, tse kang;sebopeho sa karolo, moo tšobotsi e leng teng ka har'a sesebelisoa, boemo ba eona ke bofe ka likarolo tse ling tsa karolo le haeba u pharalla ka mose ho mola oa karohano.Ha ho nahanoa ka bophelo ba lisebelisoa le litšenyehelo, ke mokhoa o motle ho lumella mamello e kholo le ho rala libakeng tse sa pheleng hantle, sebopeho kapa ts'ebetso le ho tiisa mamello feela libakeng tseo ho hlokahalang.

Zine ea rona ea die casting e fapana ka boholo ho tloha ho lithane tse 100 ho isa ho tse 300, e hlahisa lisebelisoa tsa zinc die casting bakeng sa mananeo a tlhahiso ea molumo o tlase kapa o phahameng.Re ka etsa zinki hot chamber die casting, aluminium-zinki e chesang kapa e batang kamoreng ea khatello e phahameng ea die casting, le aluminium die casting.Tlhokomelo ea ts'ebetso, litšoantšo tsa mahlakoreng a khatiso, liroboto, papiso ea phallo, lisebelisoa tse sa feleng le mananeo a tlhokomelo ea lisebelisoa li sebelisoa ho lelefatsa bophelo ba lisebelisoa, ho boloka litšenyehelo, nako, le ho fana ka lisebelisoa tsa boleng bo holimo.Ho tloha ka karolo ea kemolo le prototyping ka botlalo, ho kopanya sehlahisoa se felileng.

Lisebelisoa tsa Zinc

Re moetapele oa tlhahiso ea lihlahisoa tsa lefu la China.Metallurgists ea rona e koetlisitsoeng e netefatsa hore li-alloys tsohle li kopana le litlhaloso ka tlhahlobo e tsoelang pele ea lik'hemik'hale le 'mele.

Li-alloys tsa rona li kenyelletsa:

Zinc: Zamak 3, 5, le 7.

Zinc-Aluminium: ZA-8, ZA-12, le ZA-27.

Li-alloys tsa zinc ke tsona tse bonolo ho feta khatello e phahameng.Li fana ka ductility e phahameng, matla a ts'usumetso, 'me e ka behoa habonolo.Li-alloys tsa zinc li na le ntlha e tlase ea ho qhibiliha ho feta aluminium e ka thusang ho ntlafatsa bophelo ba lefu.

Li-alloys tsa ZA ke lisebelisoa tsa tšepe tse thehiloeng ho zinki tse nang le aluminium e phahameng ho feta li-alloys tse tloaelehileng tsa zinki.Li-alloys tsena li na le litšoaneleho tse phahameng tsa matla, hape le boima bo phahameng le thepa ea ho jara hantle.

Teko ea Phallo ea Mold ea Zinc

Teknic e sebelisa theknoloji ea ketsiso ea CAM e tsebahalang lefatšeng ka bophara ho ntlafatsa moralo oa lisebelisoa le boleng ba zinki.

Bokhoni ba ho etsisa CAM bo fana ka kutloisiso e betere ea ho tlatsa hlobo ea ente ea zinki, ho tiisa, thepa ea mochini, khatello ea mocheso le ho sotha.E tsamaisoang ka botlalo ke menu e nang le mohlala o tiileng o kopantsoeng, li-interfaces tsa CASD, le li-database tse pharaletseng, CAM e fana ka tharollo e feletseng bakeng sa mafapha a meralo, a tlhahiso le a boleng.

Tšepe Ente Mold Castings

CNC Machining le Hog-outs

Direct Metal Laser Sintering (DMLS)

P-20 Tooling

ZINC SEBAKA PHETHA

Teknic e tla laola litlhoko tsa ho qetela tsa bareki ho netefatsa hore likarolo li kopana le litlhaloso ka nako le ka mokhoa o sebetsang hantle.

Qeto ea rona ea zinc e kenyelletsa:

Powder Coating (ts'ebeliso ea motlakase)

Pente e Metsi

Chromate

E-Coat

Nickel e se nang motlakase

Chrome

Ho Hlahlobisisa Silk le Stenciling

EMI/RFI Shielding

Surface Conditioning (ho thunngoa le ho phatloha ha lifaha)