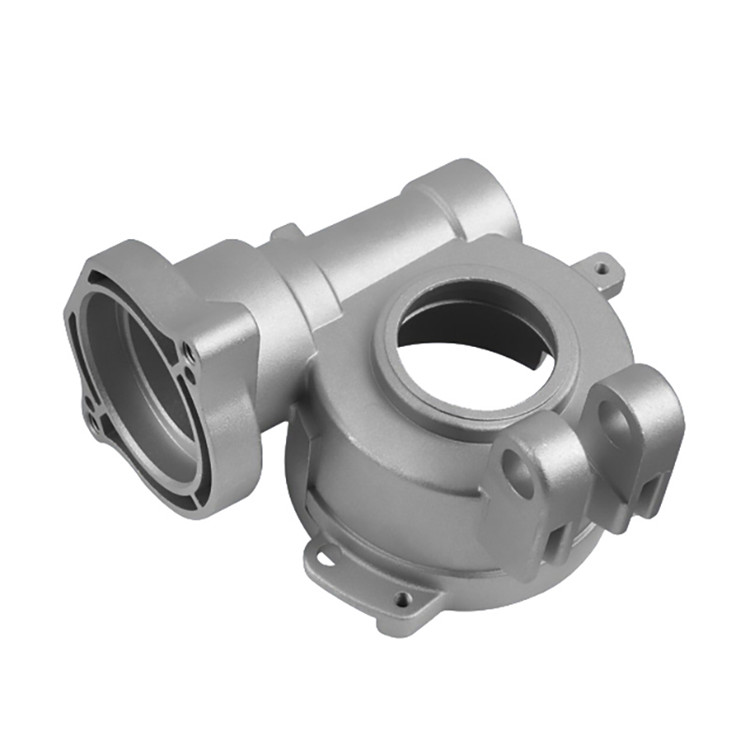

Zinc Alloy Die-Casting Parts |Professional OEM Die Casting

✧ Kenyelletso ea Sehlahisoa

Zinc die castings li sebelisoa ho hlahisa likarolo le likarolo tse fapaneng mefuteng e mengata ea lits'ebetso tsa indasteri.Thepa ea mochini oa zinc alloy die castings ka mocheso oa kamore e betere ho feta ea tšepe e bohlooho, koporo le lehlabathe la aluminium, haholo-holo mabapi le ho tiea le matla a ts'usumetso.Li matla, li thata ebile li tsitsitse ho feta lipolasetiki tse entsoeng ka ente.Litsenyehelo tse fokotsehileng le ts'ebetso e ntlafalitsoeng li e etsa sebaka se loketseng bakeng sa tšepe, koporo, motsoako oa aluminium kapa likarolo tsa polasetiki.

Melemo ea li-zinc alloy die casting

1. Ntlafatso ea thepa ea ho lahla - ka lebaka la ho phalla ha eona, li-castings tsa zinki li ka etsoa tse tšesaane, tse rarahaneng le tse rarahaneng, kahoo li felisa tlhokahalo ea ts'ebetso ea bobeli eo hangata e lokelang ho etsoa ka li-alloys tsa aluminium le magnesium.

2. Fokotsa nako ea potoloho - ka lebaka la ts'ebetso ea ho lahla ka kamoreng e chesang bakeng sa zinki, tlhahiso e ka bang likotoana tse 4 ho isa ho tse 5 ka motsotso.Ha ho bapisoa le aluminium e batang ea kamore e batang ea ho lahla (ho ntša maqephe a 2 ho isa ho a 3 ka motsotso), ho ka etsoa qeto ea hore zinki e ka eketsa chelete eohle ea polokelo ka lebaka la nako e khutšoanyane ea potoloho.

3. Eketsa bophelo ba hlobo - ka lebaka la mocheso o tlaase oa ho qhibiliha oa zinki, bophelo ba hlobo ea likarolo tsa zinki bo ka ba nako e telele ka makhetlo a 10 ho feta ea aluminium alloy castings, 'me ka nako e ka bang 5 nako e telele ho feta ea hlobo ea magnesium.

4. Boleng bo loketseng ba mochine - alloy ea zinc e matla ho feta litšepe tse ling tse tšoanang 'me ha e hloke ho sebetsa ha bobeli.Boleng bona bo boloka litšenyehelo tsohle tsa karolo ka 'ngoe.

✧ Tlhaloso ea Lihlahisoa

| Mold | SKD61, H13 |

| Cavity | E le 'ngoe kapa tse ngata |

| Nako ea Bophelo ba Mold | 50K makhetlo |

| Boitsebiso ba Sehlahisoa | 1) ADC10, ADC12, A360, A380, A413, A356, LM20, LM24 2) motsoako oa zinki 3#, 5#, 8# |

| Phekolo ea Bokaholimo | 1) Sepolishe, ho roala phofo, ho roala ka lacquer, e-coating, ho phatloha ha lehlabathe, ho phatloha ho hoholo, anodine 2) plating ea Poland + zinki / chrome plating / perela chrome plating / nickel plating / koporo plating |

| Boholo | 1) Ho ea ka litšoantšo tsa bareki 2) Ho ea ka mehlala ea bareki |

| Sebopeho sa ho taka | mohato, dwg, igs, pdf |

| Litifikeiti | ISO 9001:2015 & IATF 16949 |

| Tefo Nako | T/T, L/C, Tiisetso ea Khoebo |